From 16 Hours to 5 – An Upgrade That Truly Delivers

We love it when customers follow up after an upgrade — especially when the message sounds like this:

“We cut from 16h to 5h print hahaha. Thx, so happy of this upgrade.”

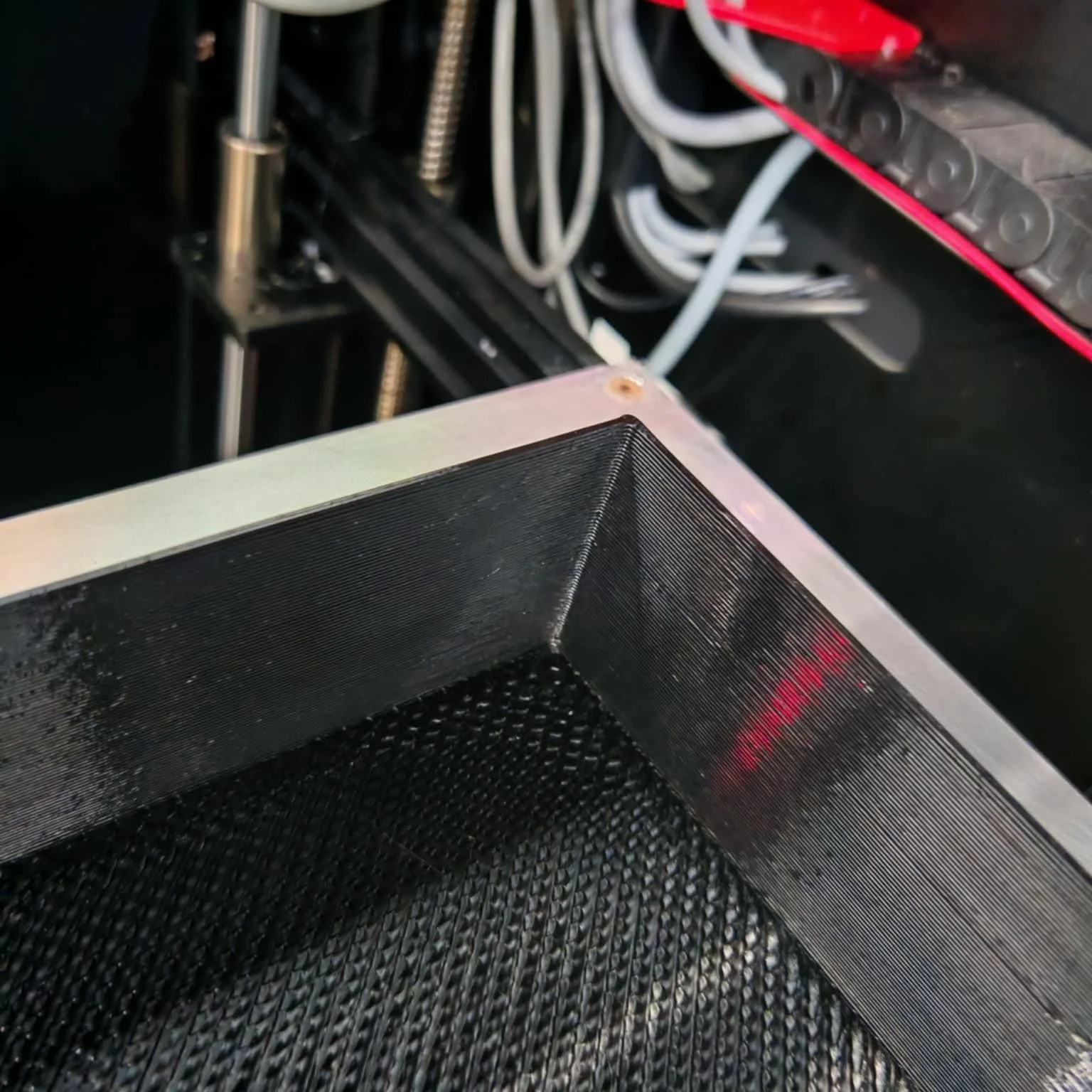

That’s exactly what happened when Simply Grow, a UK-based company, installed a new hotend setup on their Modix 120X. And they don’t just use 3D printing for prototyping — they use it in their finished, customer-ready products within hydroponics and growing systems. Time matters. And when you rely on your printer every day, it has to deliver.

From Long Waits to Efficient Production

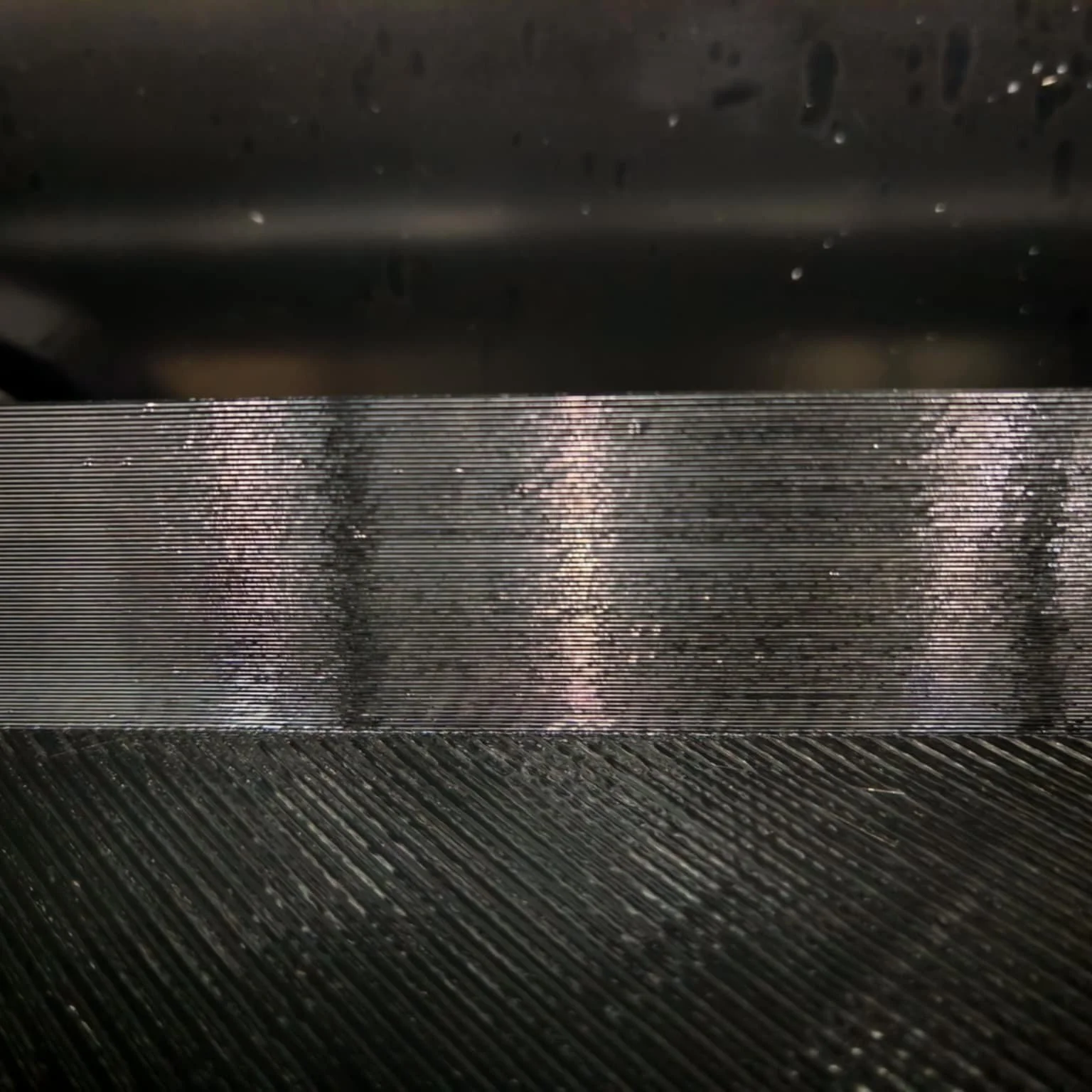

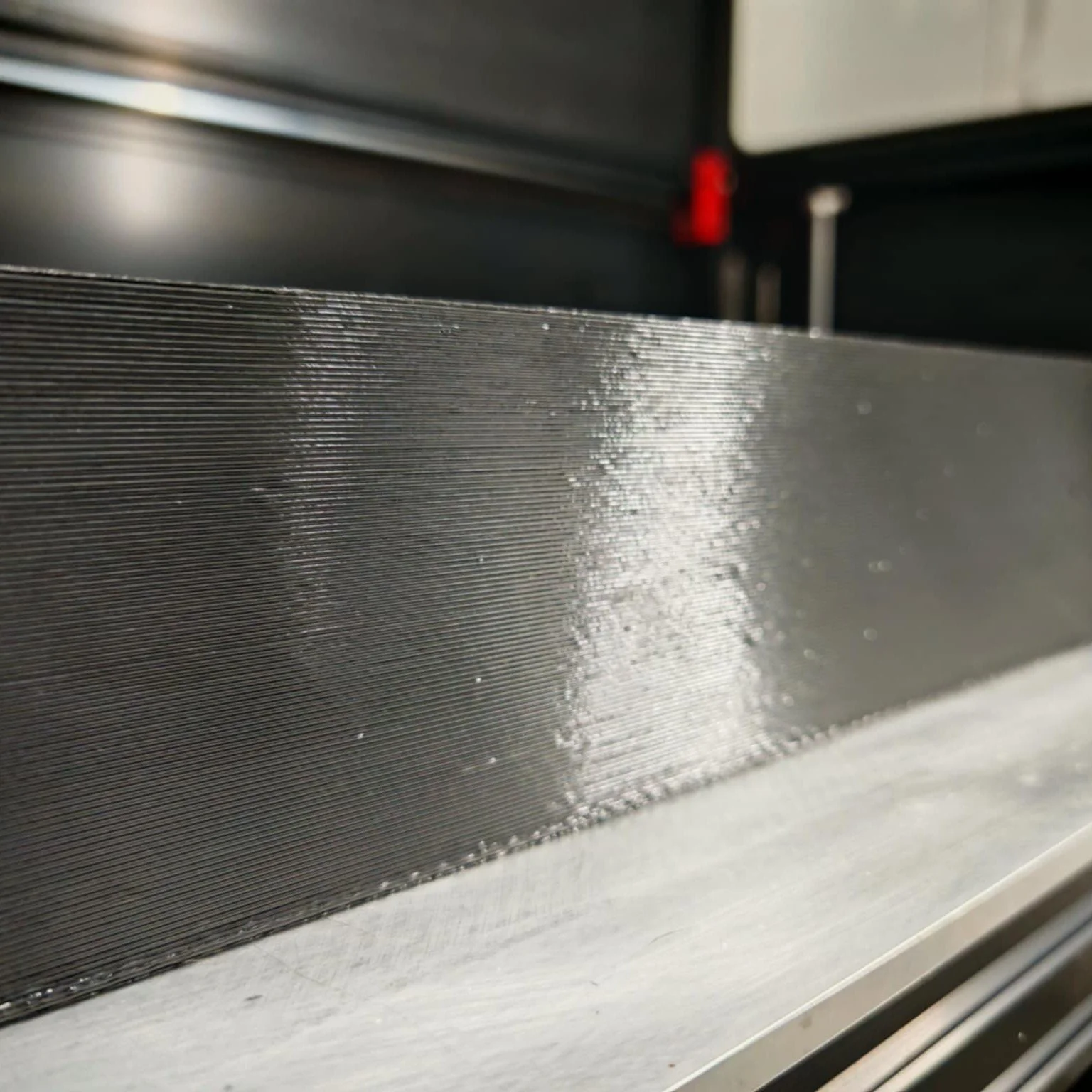

A 2.5 kg part that used to take 16 hours now prints in just 5 hours — with the same high-quality finish and rock-solid reliability.

🔁 What Does That Actually Mean for Simply Grow?

With the new setup, Simply Grow can now get more done in less time — without sacrificing precision. What previously meant 2–3 large prints over three days now fits comfortably in a single day’s work.

Let’s do the math.

They’re saving 11 hours per print, and if they run 4–6 large prints per week, that’s:

📉 44–66 hours saved every month

Let’s be conservative and say their machine time is worth only 100 SEK/hour (≈ £7.50 / €9). That means:

💰 4,400–6,600 SEK/month in saved production time

💸 Cost of upgrade: ~10,000 SEK

👉 That’s ROI in just 1.5 to 2 months

And that doesn’t even count the soft benefits: reduced print failure risk, freed-up operator time, faster delivery cycles, or increased customer satisfaction.

What Made the Difference?

This isn’t just a nozzle swap. The upgrade included several critical components that together boost flow rate, cooling, and reliability:

Chube Conduction hotend – Built with nickel-plated copper, titanium, and other exotic alloys, capable of flow rates up to 80 mm³/s without compromising performance.

LGX Pro extruder – Delivers precise, powerful filament pushing, even with high-flow nozzles and abrasive materials.

Dual 3640 server-grade fans – Combined airflow of 23.9 m³/h, designed for high static pressure to maintain stable cooling under heavy loads.

SLM-printed aluminium mounts – Custom parts for fan ducts, Beacon3D sensor mount, and cooling control. Lightweight, durable, and designed to thrive in high-temp production environments.

Beacon3D-ready – Built-in mounting support for anyone running Klipper and looking for ultra-precise Z compensation and mesh leveling.

Who Is Simply Grow?

Simply Grow is a UK-based company offering hydroponic growing solutions. They use 3D printing as a direct part of their finished product offering, not just in development. That means quality, consistency and speed are non-negotiable.

With this upgrade, they've unlocked a new level of output from the same printer — no added footprint, just more performance.

Looking to cut your print times, free up capacity, and get more out of your existing printer?

💬 Get in touch — we’ll help you find the right setup for your machine, your materials, and your production needs.